Quick-Turn PCB Assembly

When Fast PCB Assembly Actually Matters

Deadlines slip. Components run late. Your team burns the midnight oil to finalize a design, and now the prototype needs to be built yesterday. That’s where quick-turn PCB assembly makes all the difference.

You’re prepping for a pitch, validating a new concept, or trying to hit a fixed test window. Timing matters. Engineers know that even a few extra days can kill momentum or delay a product launch.

At Ninja Circuits, we specialize in

rapid PCB prototyping and building high-quality boards fast. We’re not a mass manufacturer. We’re a U.S.-based team focused on getting your design assembled and out the door so you can stay on track.

What Quick-Turn PCB Assembly Means at Ninja Circuits

Quick-turn PCB assembly at Ninja Circuits isn’t about rushing. It’s about moving fast while getting every detail right. We work with engineers who need prototypes that perform like production boards, built in days instead of weeks.

That means tight coordination, early-stage DFM reviews, and direct communication when questions come up. Our team handles both turnkey and consignment builds, manages a wide range of components, and starts moving as soon as your files land.

Alongside assembly, we also support specialized services like

PCB repair to help keep your development cycles moving without starting from scratch.

Our Quick-Turn PCB Assembly Process

We’ve built our process for speed, clarity, and control. It starts the moment you upload your files. Our engineers review your design up front and flag any issues quickly, helping you avoid unnecessary delays.

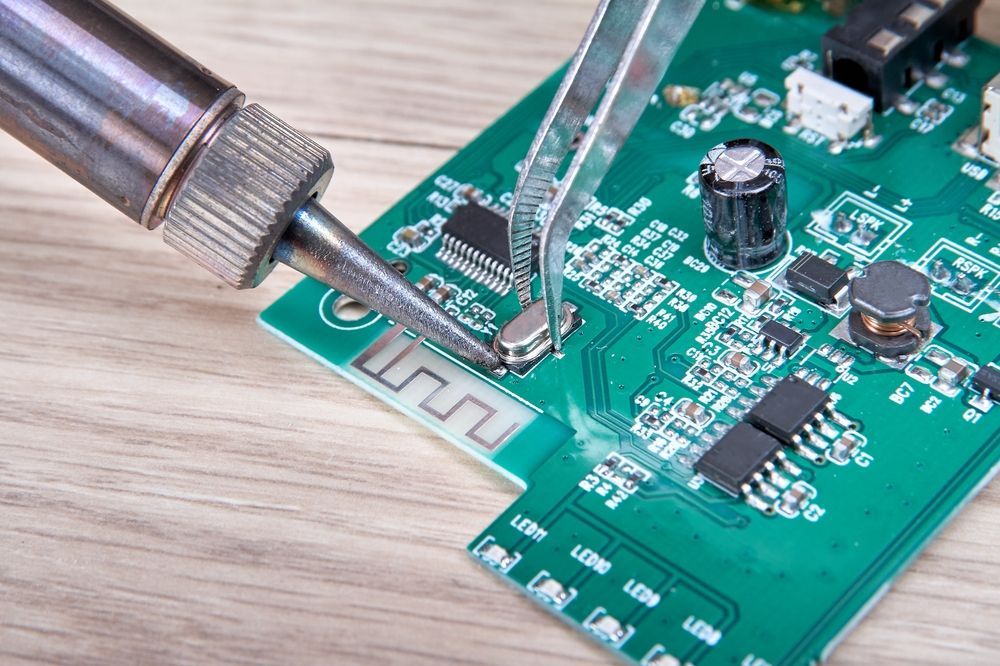

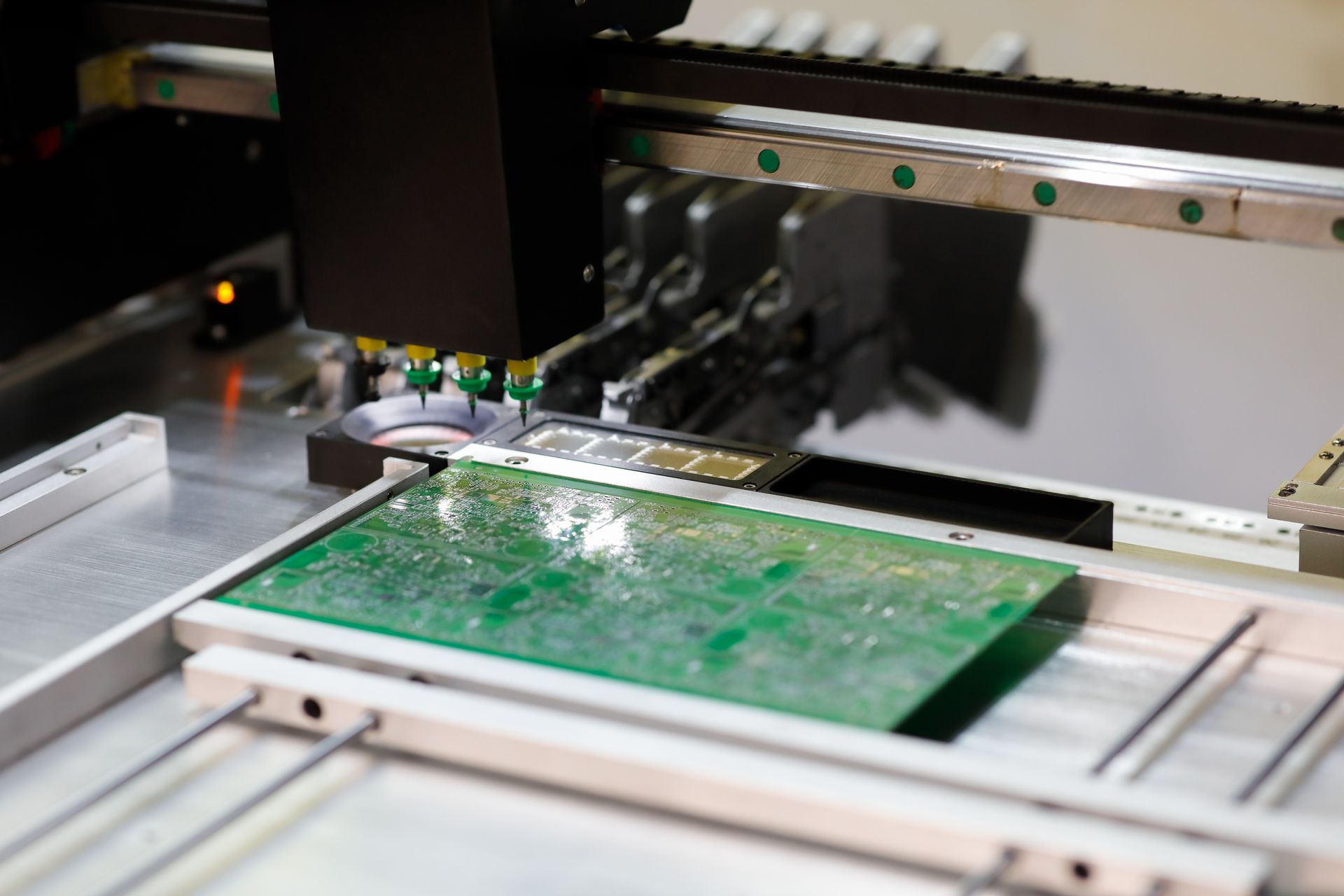

Once approved, your board moves straight into SMT. We use precision placement, vapor-phase reflow, and 3D AOI to maintain high quality on every run. Through-hole and mixed-technology builds are completed in-house as well.

Assembly happens entirely at our U.S. facility, managed by the same team that reviewed your files and guided your build from start to finish. We specialize in

low-volume PCB assembly that supports testing, iteration, and production-readiness.

Why Engineers Choose Ninja for Quick-Turn PCBs

Speed is part of it. But engineers keep coming back because they know what they’ll get: clear answers, consistent builds, and a team that actually understands hardware.

We work closely with R&D teams, startups, and established OEMs that rely on fast prototype cycles. Every project is handled with care and close attention to detail, regardless of size.

Everything we do centers on reliability. From sourcing to soldering and inspection, we focus on helping your design perform the way it was intended, right out of the box.

Start Your Quick-Turn PCB Assembly Today

Got files ready? Upload your Gerbers, BOM, and assembly notes, and our team will begin the quoting process. Ninja Circuits offers turnaround times of 24 and 48 hours, 5 days, and 10 days once materials arrive. All depends upon your scheduling needs.

If you have questions, you’ll speak directly with an engineer. We’ll review your build, flag any issues early, and keep your timeline moving.

We handle

electronic PCB assembly with speed, precision, and direct communication from start to finish.

OUR certifications

Ninja Circuits is committed to providing quality to customers. Certifications, training, and experience are what we take pride in at every step of the way for every project.

WHAT OUR CUSTOMERS SAY

We appreciated the quick and creative response you provided in building this product. I was concerned about the robustness of this assembly, but you found a solution that secured the components in the box sufficiently.

INDUSTRY INSIGHTS

Contact Ninja for a quote today!

Contact Ninja for a quote today!

Call Ninja Circuits and discuss your project needs with an in-house account representative today.

Turnkey Get a Quote

Thank you for contacting us.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.