INDUSTRY INSIGHTS

Comparing Reflow Soldering vs Wave Soldering

A

printed circuit board (PCB) can look perfect on-screen, then stumble at assembly when the soldering method does not match the design. The difference often shows up late, after parts are ordered and schedules tighten. Reflow and wave soldering can both create reliable joints, yet they fit different board layouts, part types, and production realities. Picking the wrong one rarely fails loudly. It quietly adds defects, rework, or delays that eat into the time budget.

Why Choosing the Right Soldering Method Matters

Soldering rarely feels like the headline decision early in a project. Layout, parts selection, and performance targets usually take center stage. Then the build hits the floor, and the soldering method starts shaping everything that follows.

A process mismatch can show up as skewed components, bridges, cold joints, or through-hole pins that never fully wet out. The cost is not always scrap. More often, it’s rework, extra inspection time, added labor, and a schedule that keeps slipping one day at a time.

Choosing between reflow and wave becomes a practical risk decision, tied to package types, board geometry, thermal profiles, and how much rework the timeline can realistically tolerate.

What Is Reflow Soldering?

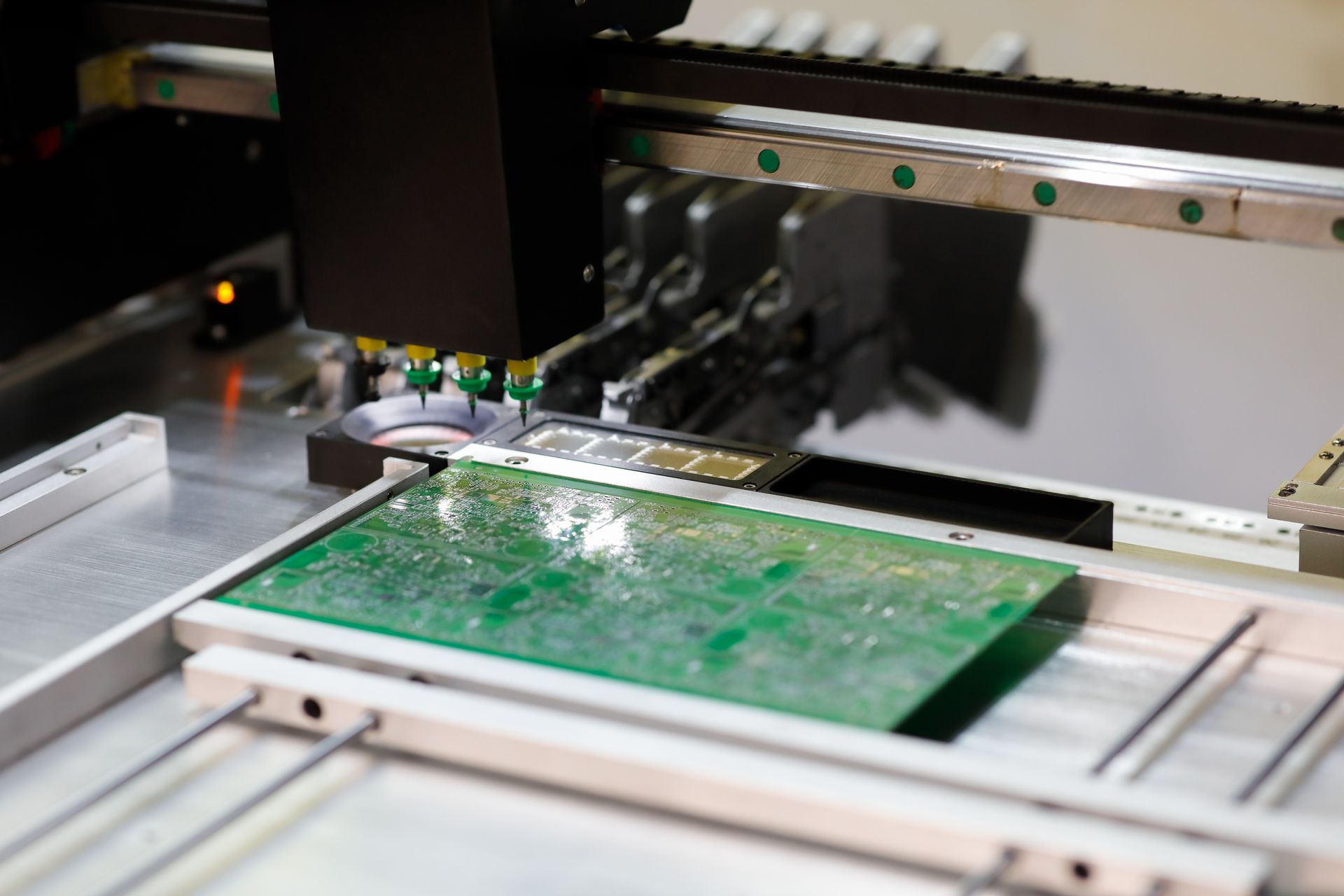

Reflow soldering is the most common method for assembling surface-mount technology (SMT) components. It uses solder paste, a mix of powdered alloy and flux, applied to pads before component placement. Once everything is aligned, the board moves through a temperature-controlled oven. The paste melts, reflows, and solidifies to create reliable solder connections.

The process works well for dense boards, fine-pitch parts, and mixed technologies that include BGAs or QFNs. It’s also better suited for double-sided assemblies, since the oven can be tuned to avoid disturbing parts already soldered on the opposite side. Reflow offers precise thermal control, which helps reduce stress on sensitive components and supports tighter design tolerances in compact PCB layouts. In some cases,

vapor phase reflow soldering is used to improve temperature uniformity and prevent overheating during assembly.

What Is Wave Soldering?

Wave soldering is typically used for through-hole components, though it can also handle some surface-mount parts using adhesives. In this method, the bottom of the populated PCB passes over a flowing “wave” of molten solder. As the board moves across, exposed leads and pads come into direct contact with the solder, creating consistent, conductive joints in a single pass.

This process is fast, consistent, and well-suited for boards with many through-hole parts. It’s often preferred in high-volume manufacturing or when component leads need mechanical strength. However, wave soldering has limitations with densely packed SMT layouts and isn’t ideal for double-sided assemblies where parts on the underside could detach or misalign during soldering.

Reflow Soldering vs Wave Soldering: Key Differences

Both methods are used to create strong electrical connections, but their mechanics, applications, and constraints differ in meaningful ways. The best choice depends on the components involved, board design, thermal sensitivity, and production goals. Materials, part density, and layout complexity also influence which method is more reliable across different build scenarios and manufacturing environments. Here's how they compare:

| Feature | Reflow Soldering | Wave Soldering |

|---|---|---|

| Best For | Surface-mount components (SMT) | Through-hole components |

| Process Type | Controlled heating in the reflow oven | Solder wave contract |

| Double-Sided Compatability | Excellent | Limited |

| Fine-Pitch Support | High | Limited |

| Speed in High Volume | Moderate | Fast |

This comparison helps align design decisions with the right assembly method from the start.

Reflow vs Wave Soldering for Modern PCB Designs

Modern PCB layouts often include fine-pitch components, double-sided placements, and thermal-sensitive devices that push the limits of traditional soldering methods. The soldering approach needs to align with design realities, not just legacy process choices. Here’s how each method fits current design demands:

- Reflow soldering is ideal for compact boards, mixed-package types, and higher component density.

- Thermal profiles can be adjusted to protect sensitive components.

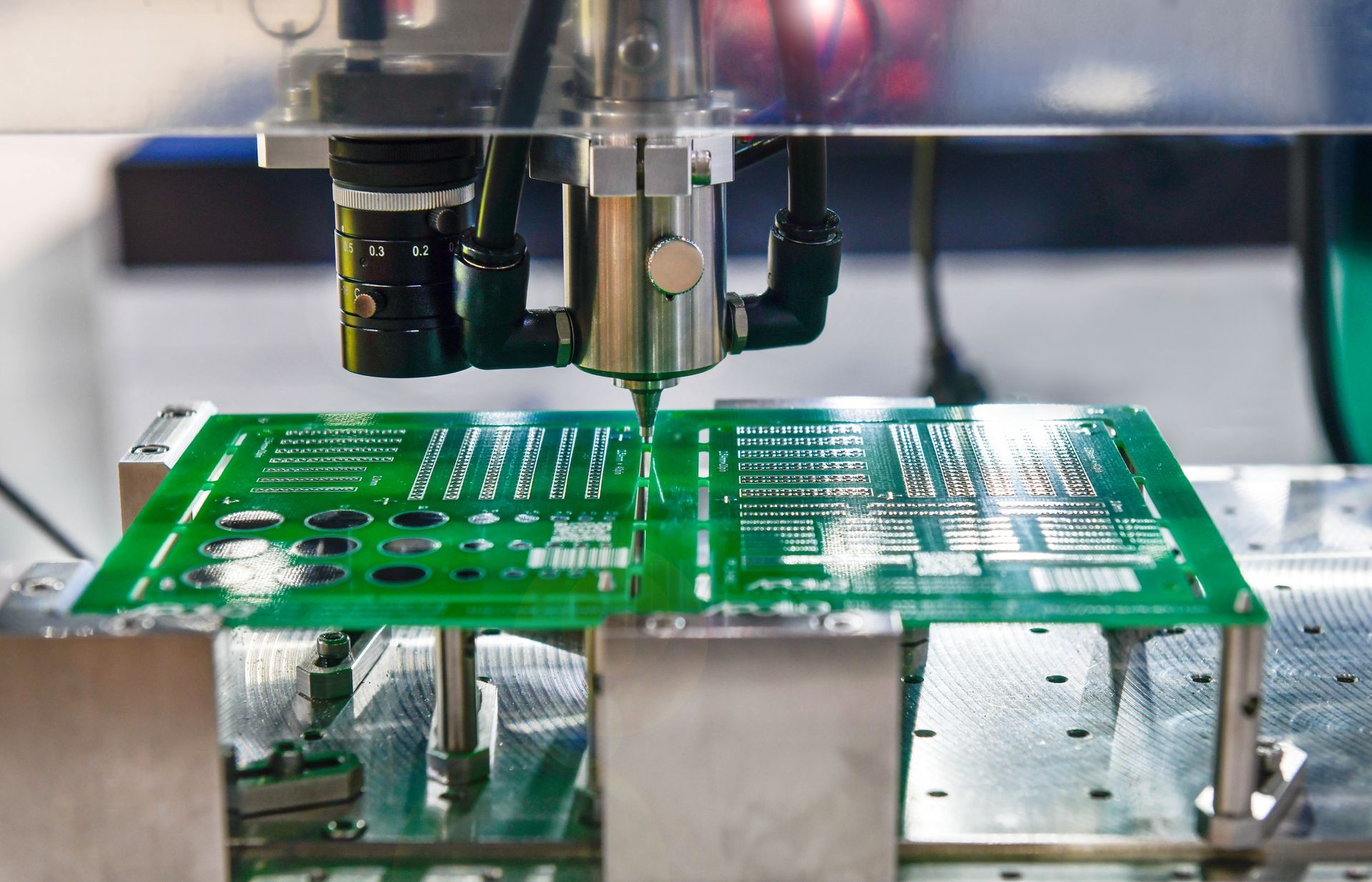

- It's compatible with automated pick-and-place workflows for faster throughput.

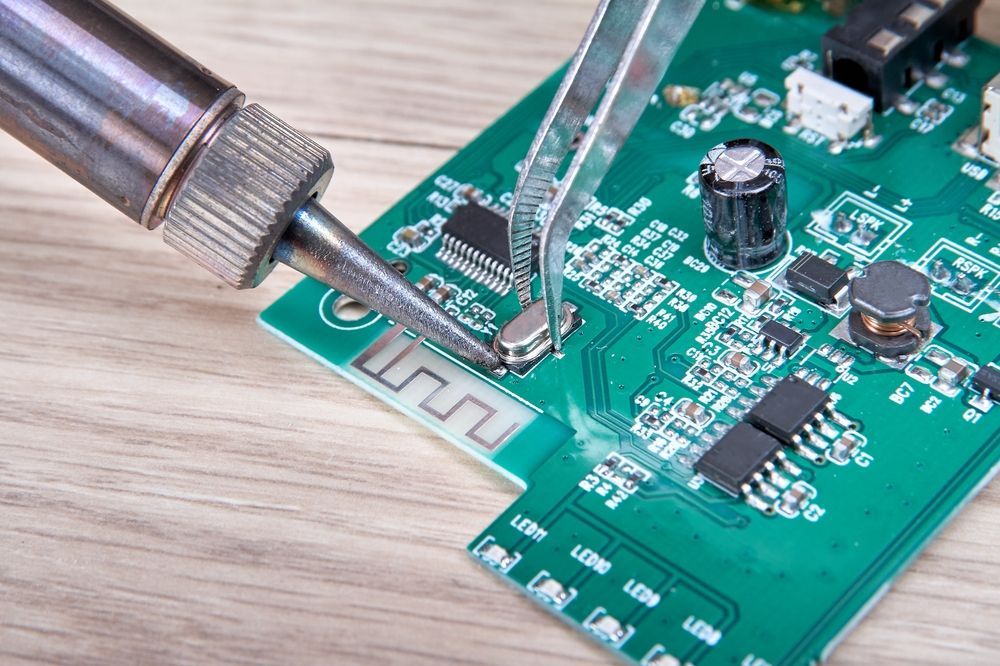

- Manual touch-up may be required for certain components after wave soldering.

- Wave soldering remains useful for designs that rely heavily on through-hole connectors or high mechanical strength.

- It's still preferred in some high-volume workflows that use mostly one-sided layouts.

- It supports double-sided assemblies without disturbing previously placed parts.

Matching the method to the design helps reduce rework, inspection steps, and unexpected late-stage issues.

Cost Speed and Quality Considerations

Both soldering methods offer tradeoffs that affect total cost and throughput. Reflow tends to require more precise thermal control and upfront setup for paste application and profile tuning, which adds cost for lower volumes but pays off when dealing with fine-pitch or densely packed boards. It also allows for better control over thermal stress, which contributes to long-term reliability.

Wave soldering is faster for through-hole-dominant boards, especially in high volumes, but may introduce more variability in mixed-technology builds. Cleanup and masking steps can also add labor time. The most cost-effective process often depends on how repeatable the design is and how many factors, such as part types and orientation, are stable during production.

Choosing the Right Soldering Method for Your PCB

The right soldering method depends on more than just part type or board style. It’s about how the design, timeline, and build volumes work together. Reflow is often better for modern PCB assembly involving dense layouts, fine-pitch parts, temperature-sensitive components, or double-sided placement. Wave soldering still fits well when through-hole strength matters or when the layout is simpler, consistent, and geared toward scale.

For early-stage PCB prototyping, flexibility matters more than speed or automation. Choosing the wrong process too early can introduce rework, assembly delays, or reliability issues that are harder to fix later. Engineers benefit from understanding not just how these methods work but where each one fits best across the design, prototyping, and production cycle.

Talk to an Assembly Expert at Ninja Circuits

Soldering is one part of a larger build, but it often defines how smoothly everything else goes. The right process can reduce rework, improve yields, and give your team more confidence moving from prototype to production. That decision doesn’t have to happen in isolation or wait until the last minute.

At

Ninja Circuits, our engineers work directly with product teams to help align design choices with the most reliable and efficient assembly process. Whether you're planning a single prototype or scaling a short run, we’re here to assist your team in choosing the approach that works.

Need help evaluating your next build?

Contact us to speak with a real engineer about which soldering method best fits your board.

INDUSTRY INSIGHTS