Medical Device PCB Assembly

We’re Experienced in Building Medical Device PCB Assemblies

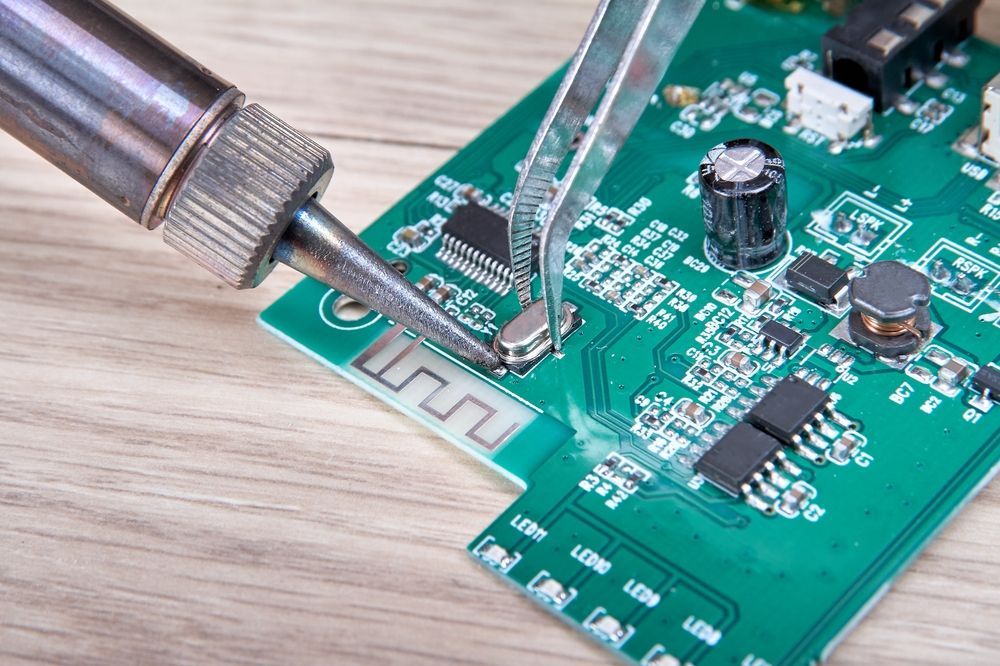

When your design ends up in a hospital, clinic, or patient’s hands, every signal has to be right. At Ninja Circuits, our focus on precision assembly for medical prototypes is built on controlled processes, consistent inspection, and repeatable quality. We specialize in small-batch builds that help engineers prove accuracy, stability, and safety before production. Each board we assemble represents technology that could improve or protect a life, and we approach that responsibility with the same care you put into the design itself. With more than 30 years of experience and IPC-certified technicians, we deliver prototypes that perform as your engineering team designed them to, are assembled fast enough to keep your project moving forward, and are built accurately to earn your confidence.

Medical pcba Applications We Support

Diagnostic Equipment

Boards used in analyzers, test instruments, and lab automation systems require signal accuracy and repeatable performance. Our prototypes help you validate sensitivity and reliability before production.

Wearable Devices

Compact, low-power circuits drive modern medical wearables. We assemble small, complex boards that help you confirm comfort, efficiency, and consistent operation under real use.

Monitoring Devices

Vital sign and telemetry systems rely on continuous uptime and accurate data. We build prototypes that support extended testing for stability and low noise.

Imaging Systems

High-frequency, high-density assemblies are essential for ultrasound and imaging platforms. We deliver clean, precisely assembled boards to maintain fidelity and processing speed.

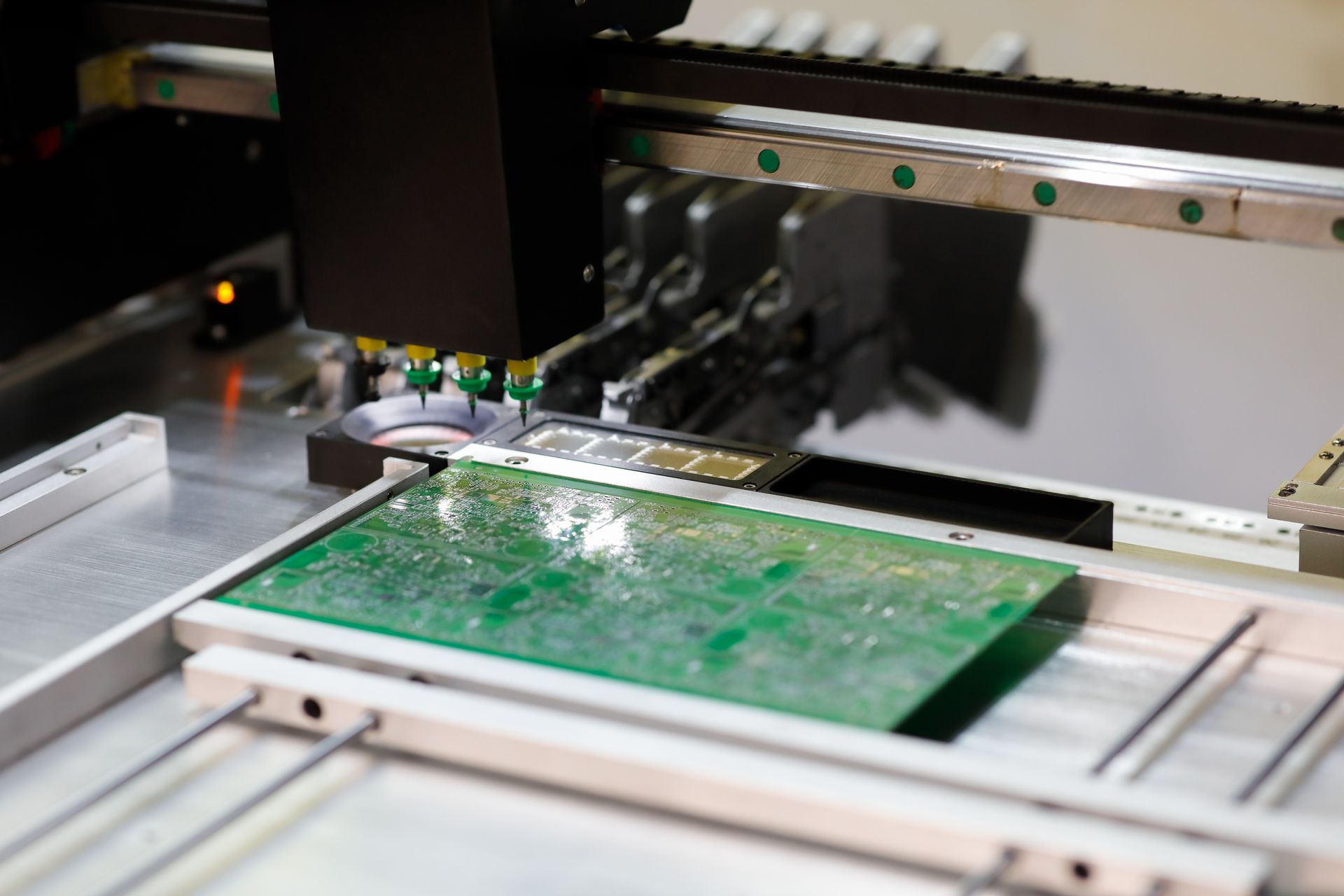

Testing Standards That Safeguard Medical Quality

In medical development, validation depends on trust, and that trust starts with the build. Each prototype that leaves our floor is inspected with the same focus you bring to design. We use 3D automated optical inspection to verify component alignment and solder integrity, X-ray imaging for BGAs and leadless devices, and microscope-level visual checks on every board. Electrical continuity and isolation are confirmed through flying probe or fixture-based testing, giving you reliable data before verification or certification. Assemblies can be produced to IPC-A-610 Class II or III and prepared with conformal coating, serialization, and documentation for regulated environments.

THE NINJA WAY

Ninja Circuits is a flexible, fast, and skilled pcb assembly manufacturer dedicated to developing the best and quickest pcb assembly prototypes in the USA. We offer exceptionally fast pcb assembly prototypes to engineers and innovators developing new products to improve and enhance our lives and the world we live in. Ninja Circuits is proud to be based in the USA, which allows Ninja Circuits to provide excellent communication, on-time delivery, quick turn PCB assembly, and responsive customer service.

Flexible

Flexibility is our strength. No two customers are alike. Ninja will tailor our services to your needs to provide you with the desired outcome for your project.

Fast

Ninja Circuits knows that the culmination of your project design is a working prototype. Waiting weeks or months for validation is not only frustrating but impedes schedules and time to market and is unacceptable. Ninja can provide you a quality product in as short amount of time possible.

SKILLED

Our personnel are trained with skills on par with anyone in the EMS industry. A poorly assembled product is a failure. Ninja delivers fast AND quality products every day and will ensure your project needs are met.

OUR certifications

Ninja Circuits is committed to providing quality to customers. Certifications, training, and experience are what we take pride in at every step of the way for every project.

WHAT OUR CUSTOMERS SAY

We appreciated the quick and creative response you provided in building this product. I was concerned about the robustness of this assembly, but you found a solution that secured the components in the box sufficiently.

INDUSTRY INSIGHTS

Contact Ninja for a quote today!

Get a Quote Today and Build Faster with Ninja

In medical R&D, timing often determines progress. Every week saved in prototyping shortens the path to testing, approval, and patient use. That’s why we keep our process straightforward with 48-hour quotes, quick assembly once materials arrive, and overnight shipping when needed. No waiting in production queues or competing with volume orders. Our U.S.-based technicians review your files carefully, communicate clearly, and build each board with precision. The result is a prototype you can trust that’s built quickly enough to keep your momentum and accurate enough to prove your design.

If you need it fast, call Ninja. Send your files and start your build today.

Turnkey Get a Quote

Thank you for contacting us.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.