Aerospace and Aviation PCB assembly

We're Experienced in Building Aerospace and Aviation PCB Assemblies

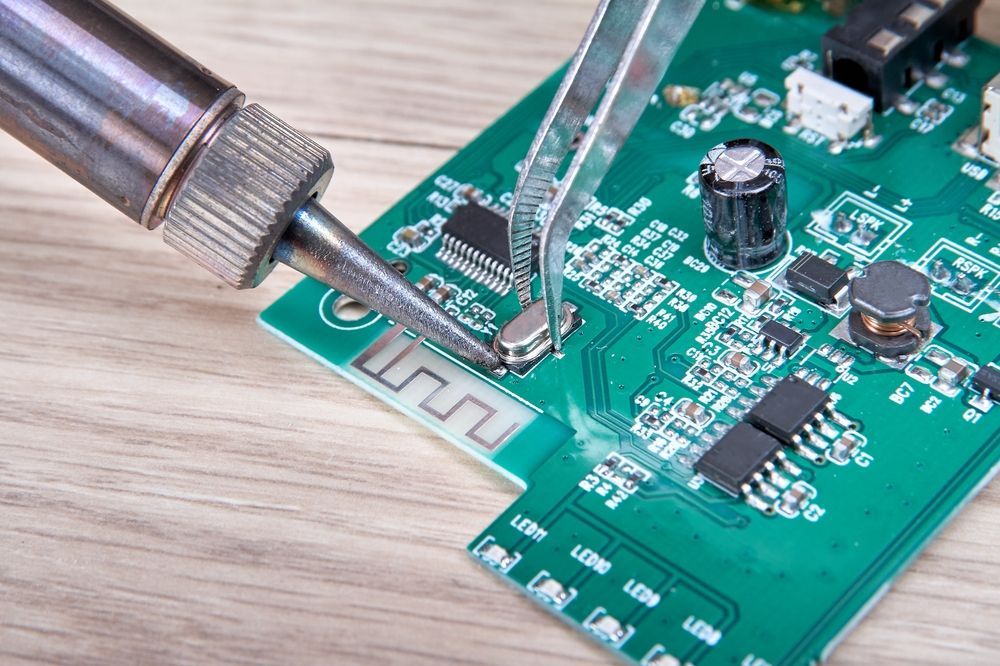

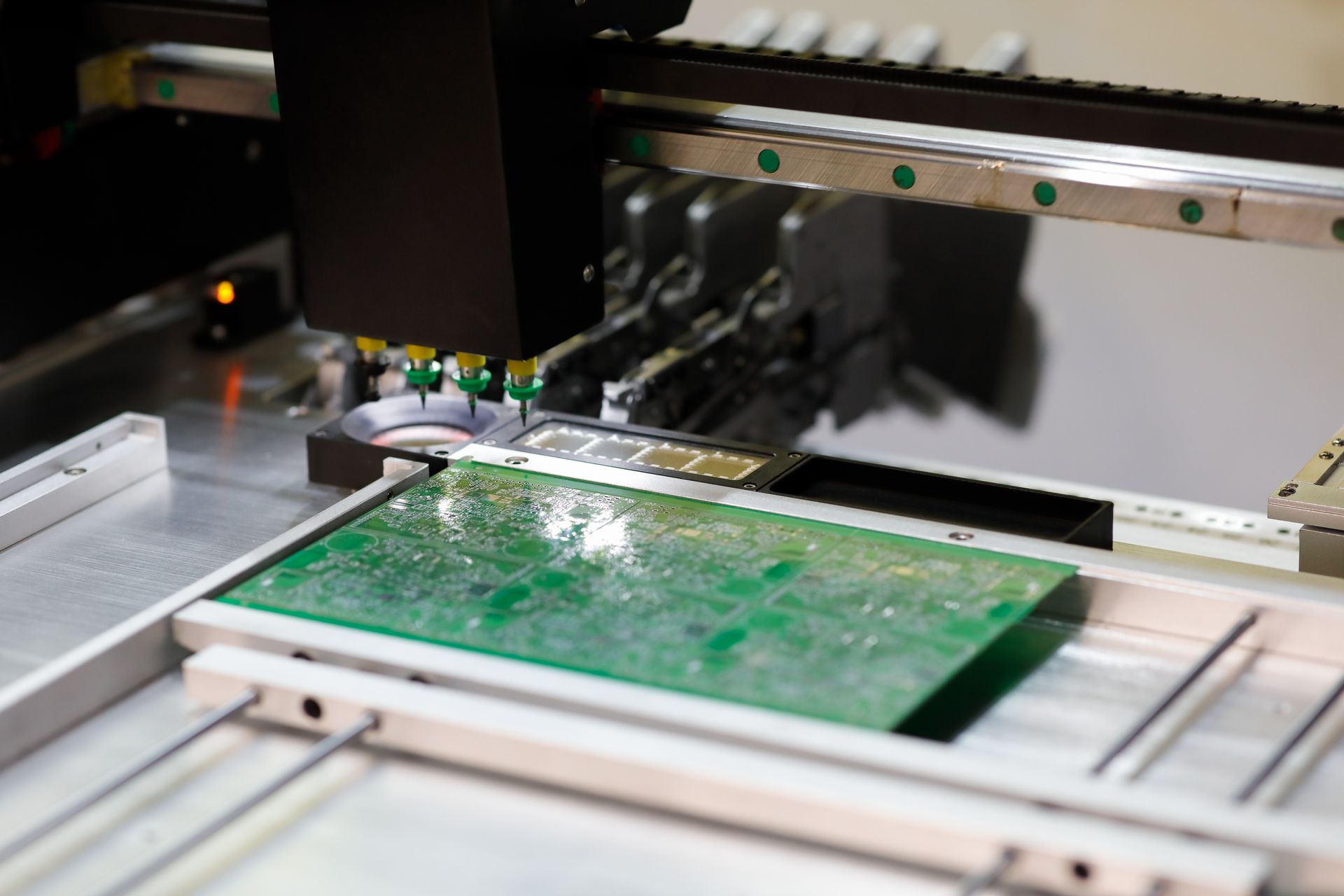

Altitude, vibration, and mission-critical conditions all leave no room for error when it comes to the components that power, guide, and stabilize flight. And in the aerospace and aviation industries, every circuit must perform flawlessly under pressure. At Ninja Circuits, we assemble the prototypes that help engineers validate control, communication, and navigation systems under strict requirements for safety and performance. Our process emphasizes precision, repeatability, and full traceability from the first component placed to final inspection. With more than 30 years of experience, IPC-certified technicians, and ITAR-ready documentation, we deliver small-batch aerospace and aviation prototypes that meet demanding industry standards and maintain schedule integrity for your next round of testing.

Aerospace & Aviation PCBA Applications We Support

Avionics Systems

Boards for flight displays, data management, and communication systems demand high reliability. Our assemblies help engineers confirm accuracy and resilience in complex signal environments.

Satellite and Space Systems

Prototypes for orbital and high-altitude equipment must endure temperature shifts and radiation exposure. We assemble boards with attention to component placement, solder quality, and long-term stability.

Flight Controls

Actuation and stability systems rely on consistent timing and verified connectivity. We build prototypes that let you test precision under dynamic loads.

Navigation Equipment

Positioning, guidance, and sensor integration require exact alignment and signal clarity. Our builds maintain integrity across multilayer, mixed-technology designs.

Testing Standards that Meet Aerospace Requirements

Aerospace hardware demands the highest level of inspection and documentation. Every board assembled at Ninja Circuits is reviewed under a microscope for placement and solder accuracy, analyzed through 3D automated optical inspection, and verified with X-ray imaging for BGAs and leadless devices. Electrical integrity is tested through flying probe or fixture-based methods to confirm continuity, isolation, and net performance. Assemblies are produced to IPC-A-610 Class II or Class III, finished with conformal coating, serialization, and traceable documentation to meet aerospace compliance standards. Each inspection and verification step supports reliability under the most demanding operating conditions.

THE NINJA WAY

Ninja Circuits is a flexible, fast, and skilled pcb assembly manufacturer dedicated to developing the best and quickest pcb assembly prototypes in the USA. We offer exceptionally fast pcb assembly prototypes to engineers and innovators developing new products to improve and enhance our lives and the world we live in. Ninja Circuits is proud to be based in the USA, which allows Ninja Circuits to provide excellent communication, on-time delivery, quick turn PCB assembly, and responsive customer service.

Flexible

Flexibility is our strength. No two customers are alike. Ninja will tailor our services to your needs to provide you with the desired outcome for your project.

Fast

Ninja Circuits knows that the culmination of your project design is a working prototype. Waiting weeks or months for validation is not only frustrating but impedes schedules and time to market and is unacceptable. Ninja can provide you a quality product in as short amount of time possible.

SKILLED

Our personnel are trained with skills on par with anyone in the EMS industry. A poorly assembled product is a failure. Ninja delivers fast AND quality products every day and will ensure your project needs are met.

OUR certifications

Ninja Circuits is committed to providing quality to customers. Certifications, training, and experience are what we take pride in at every step of the way for every project.

WHAT OUR CUSTOMERS SAY

We appreciated the quick and creative response you provided in building this product. I was concerned about the robustness of this assembly, but you found a solution that secured the components in the box sufficiently.

INDUSTRY INSIGHTS

Contact Ninja for a quote today!

Get a Quote Today and Build Faster With Ninja

Development in aerospace moves through tight testing cycles and strict oversight. We support that process with 48-hour quotes, quick-turn assembly after materials arrive, and overnight shipping for quick turnaround. Our U.S.-based technicians review your data packages closely, communicate directly with your team, and assemble every board to the standards required for flight-critical applications. The result is a reliable, fully verified prototype that keeps your testing and certification timeline on course.

Start your next build with Ninja and see how fast precision can be.

Turnkey Get a Quote

Thank you for contacting us.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.