High Tech PCB Assembly

We're Experienced in Building High Tech PCB Assemblies

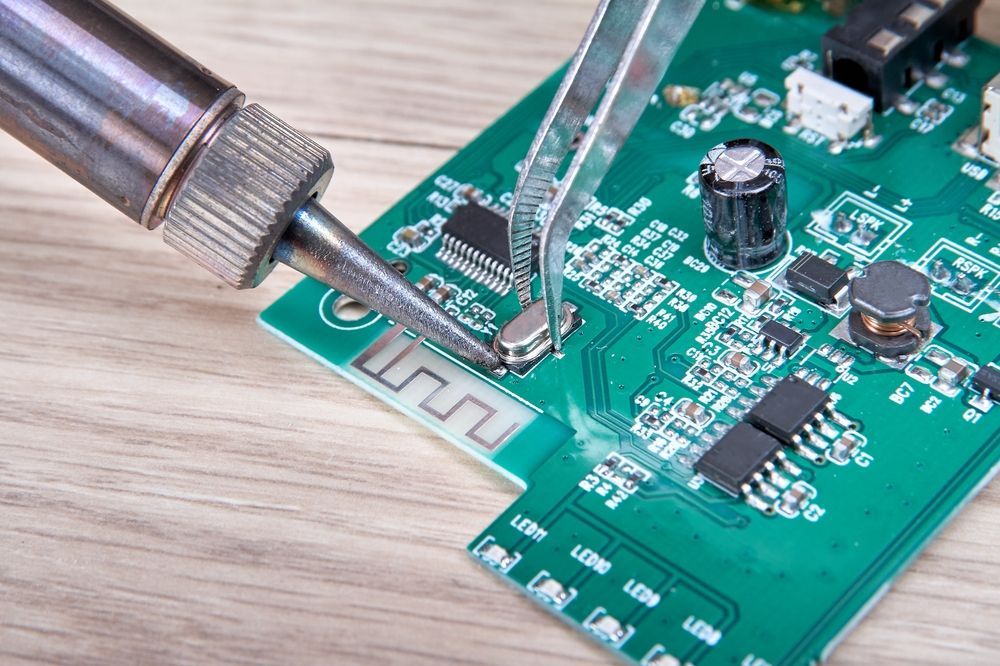

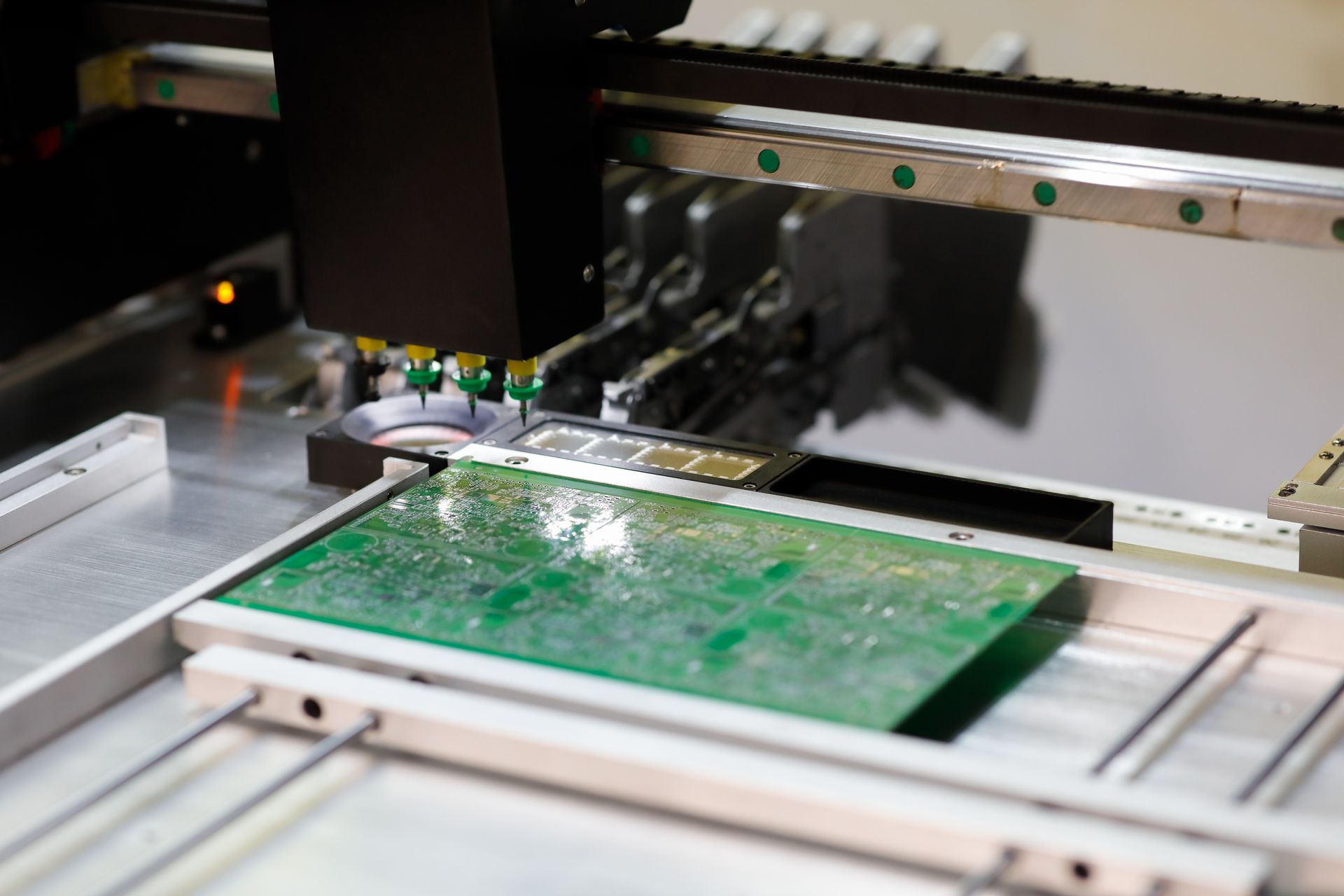

Every new generation of technology depends on someone turning an idea into working hardware. At Ninja Circuits, we work with the engineers alongside that progress, assembling complex, high-density prototypes for computing, semiconductors, consumer devices, and IoT systems. Our focus is precision assembly built on controlled processes, repeatable results, and attention to every detail that affects performance. Each board we assemble supports the products that keep people connected, informed, and productive. With more than 30 years of experience, IPC-certified technicians, and consistent process oversight, we deliver small-batch prototypes that perform as designed, assembled fast enough to keep development moving.

High Tech PCBA Applications We Support

Consumer Electronics

We assemble compact, mixed-technology boards that help engineers validate performance, connectivity, and power efficiency in next-generation devices.

Semiconductors

Prototyping for semiconductor control and test systems demands clean signal paths and repeatable solder accuracy. Our builds maintain precision across every layer.

Computing

Boards for data processing, embedded systems, and control logic require tight tolerances and thermal management. Our assemblies support early verification for stability and throughput.

IoT Devices

Miniaturized, low-power assemblies are critical to connected devices. We build and inspect secure, scalable, and robust prototypes that ensure signal integrity, reliability, and seamless integration.

Testing Standards That Support Cutting-Edge Designs

High-tech prototypes push the limits of component density and precision. Each board we assemble undergoes detailed inspection using 3D automated optical inspection to confirm solder quality and alignment, X-ray imaging for leadless and BGA components, and microscope-level review for every placement. We perform electrical testing through flying probe or fixture-based methods to confirm continuity and isolation. Assemblies can be produced to IPC-A-610 Class II or III and completed with conformal coating and serialization. Every inspection step supports the level of precision your design will require before moving to mass production.

THE NINJA WAY

Ninja Circuits is a flexible, fast, and skilled pcb assembly manufacturer dedicated to developing the best and quickest pcb assembly prototypes in the USA. We offer exceptionally fast pcb assembly prototypes to engineers and innovators developing new products to improve and enhance our lives and the world we live in. Ninja Circuits is proud to be based in the USA, which allows Ninja Circuits to provide excellent communication, on-time delivery, quick turn PCB assembly, and responsive customer service.

Flexible

Flexibility is our strength. No two customers are alike. Ninja will tailor our services to your needs to provide you with the desired outcome for your project.

Fast

Ninja Circuits knows that the culmination of your project design is a working prototype. Waiting weeks or months for validation is not only frustrating but impedes schedules and time to market and is unacceptable. Ninja can provide you a quality product in as short amount of time possible.

SKILLED

Our personnel are trained with skills on par with anyone in the EMS industry. A poorly assembled product is a failure. Ninja delivers fast AND quality products every day and will ensure your project needs are met.

OUR certifications

Ninja Circuits is committed to providing quality to customers. Certifications, training, and experience are what we take pride in at every step of the way for every project.

WHAT OUR CUSTOMERS SAY

We appreciated the quick and creative response you provided in building this product. I was concerned about the robustness of this assembly, but you found a solution that secured the components in the box sufficiently.

INDUSTRY INSIGHTS

Contact Ninja for a quote today!

Get A Quote Today and Build Faster With Ninja

When development moves fast, prototyping should keep pace. We provide 24-hour quotes, 48-hour assembly once materials arrive, and overnight shipping to keep your schedule on track. Our U.S.-based technicians review each design carefully and communicate directly throughout the process. Every board is assembled to meet the same standards your engineering team expects in production. The result is a reliable, fully verified prototype that helps you advance testing and integration without delay.

If you need it fast, call Ninja. Get a quote today and start building in as little as 24 hours.

Turnkey Get a Quote

Thank you for contacting us.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.