vapor phase

reflow soldering

Ninja Circuits utilizes advanced vapor phase reflow soldering to ensure consistent, high-quality soldering for delicate components. This precision process provides superior heat distribution, minimizing the risk of damage while delivering optimal results for complex PCBs.

our vapor phase process

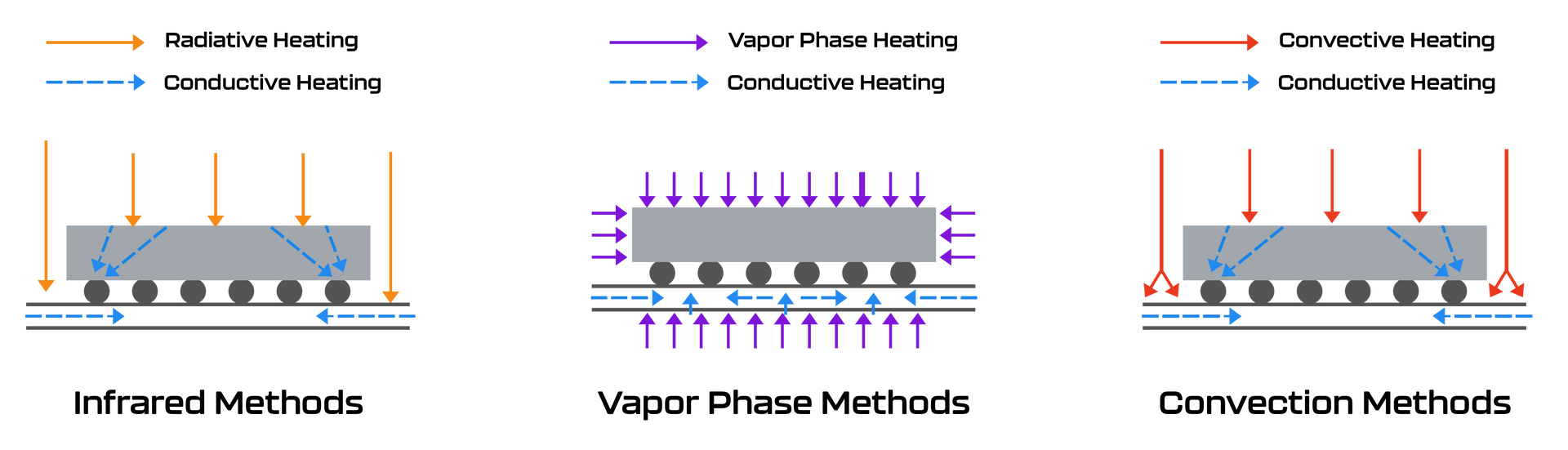

Vapor phase reflow refers to an advanced PCB soldering technology that uses an inert liquid with a high boiling point. Vapor phase reflow soldering ensures that the PCB board and its members don’t face temperatures higher than necessary. For that reason, parts don’t overheat.

Why Use Vapor Phase Reflow?

To solder electronic components to PCBs, manufacturers usually need to use high temperatures. It’s a complex process that has become even more challenging as electronic components become smaller.

The vast majority of manufacturers now opt for leadless solder bases. These bases require even higher temperatures to melt the solder effectively. As a result, the risk of damage to the electronic units due to overheating is higher.

Vapor phase reflow technology helps counter this problem by virtually eliminating temperature fluctuations, topography, and board layout.

Benefits of Vapor Phase

- Vapor Phase Reflow produces high-quality solder joints for challenging parts.

- Allows for precise temperature control during the assembly process.

- Maintains consistent actual temperature across the entire PCB, regardless of:

- Size

- Shape

- Surface area

- Ensures that every component, no matter its

size,

density, or

location, receives the same temperature.

THE NINJA WAY

Ninja Circuits is a flexible, fast, and skilled pcb assembly manufacturer dedicated to developing the best and quickest pcb assembly prototypes in the USA. We offer exceptionally fast pcb assembly prototypes to engineers and innovators developing new products to improve and enhance our lives and the world we live in. Ninja Circuits is proud to be based in the USA, which allows Ninja Circuits to provide excellent communication, on-time delivery, quick turn PCB assembly, and responsive customer service.

Flexible

Flexibility is our strength. No two customers are alike. Ninja will tailor our services to your needs to provide you with the desired outcome for your project.

Fast

Ninja Circuits knows that the culmination of your project design is a working prototype. Waiting weeks or months for validation is not only frustrating but impedes schedules and time to market and is unacceptable. Ninja can provide you a quality product in as short amount of time possible.

SKILLED

Our personnel are trained with skills on par with anyone in the EMS industry. A poorly assembled product is a failure. Ninja delivers fast AND quality products every day and will ensure your project needs are met.

OUR certifications

Ninja Circuits is committed to providing quality to customers. Certifications, training, and experience are what we take pride in at every step of the way for every project.

WHAT OUR CUSTOMERS SAY

We appreciated the quick and creative response you provided in building this product. I was concerned about the robustness of this assembly, but you found a solution that secured the components in the box sufficiently.

INDUSTRY INSIGHTS

Contact Ninja for a quote today!

Call Ninja Circuits and discuss your project needs with an in-house account representative today.

Vapor Phase Get a Quote

Thank you for contacting us.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.